Through the implementation of anaerobic digesters, CalBioGas Hilmar LLC (Hilmar Cluster), working with Hilmar dairy farmers, are leading the way toward a more sustainable future for their surrounding community. Cluster projects consist of a hub facility for centralized operations, including the collection of biogas from multiple dairy digesters. The hub handles the cleaning, conditioning, upgrading, and pipeline injection, making it feasible and efficient for farmers to adopt this sustainable technology on their property.

Grants administered by the Dairy Digester Research and Development Program (DDRDP) under the Office of Agricultural Resilience and Sustainability (OARS) significantly contributed to the development of the Hilmar cluster (Picture 1).

In 2019, the Hilmar Cluster was awarded more than $6.0 million total in grant funding for five projects: Ahlem Farms Dairy Biogas, Charles Ahlem Ranch Dairy Biogas, Clauss & Sunwest Dairy Biogas, James Ahlem Dairy Biogas & Nyman Brothers Dairy Biogas through DDRDP for the development of the cluster (Picture 2). Given the capital-intensive nature of these projects, DDRDP grants have played a pivotal role in getting more projects built on California dairy farms.

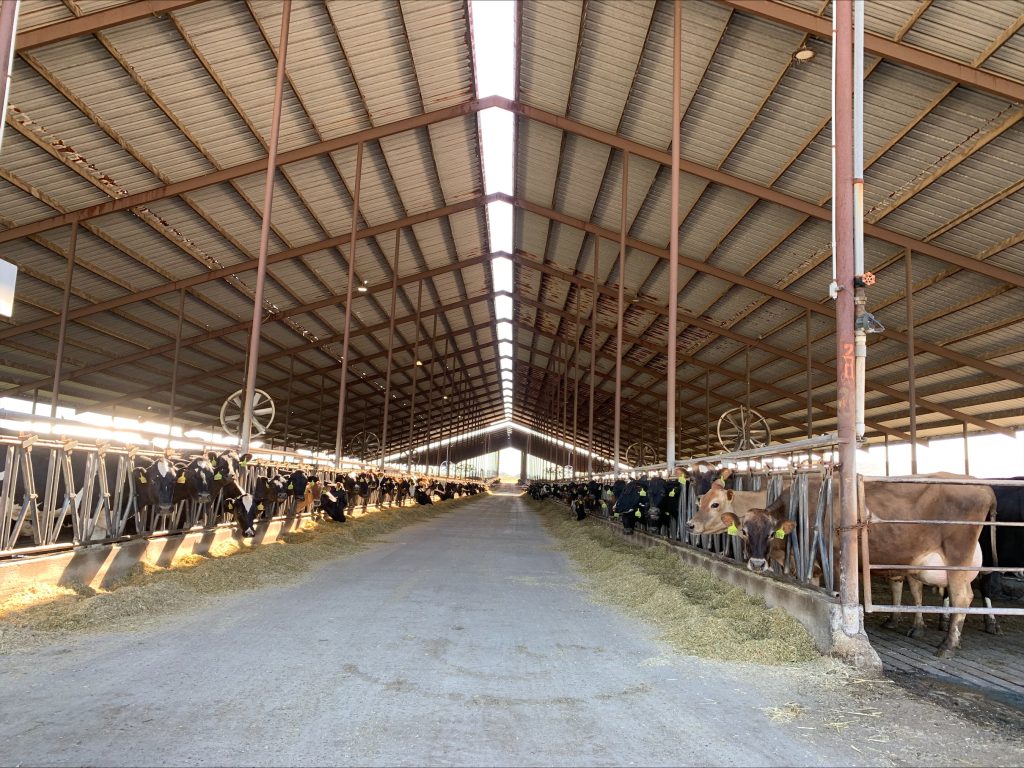

Comprised of eight (8) family farms (5 funded through DDRDP) and a strategic relationship with California Bioenergy (CalBio) and Chevron USA, the Hilmar cluster is simultaneously producing a new source of clean fuel in the form of renewable natural gas (RNG) while also reducing methane emissions. The dairy industry has continuously answered the call to do their part in progressing California’s climate goals with the Hilmar cluster being another prime example of farmers being catalysts for a cleaner future that will benefit the environment for generations to come. In the Hilmar cluster, each project is equipped with a covered lagoon that is double lined on the bottom with high density polyethylene plastic to ensure no leakage into the water table, thereby protecting and maintaining the water quality. As the manure flows into this lagoon, microorganisms will break down the manure to create biogas (primarily composed of methane, carbon dioxide (CO2), and hydrogen sulfide gases). The biogas is then captured, cleaned (with the hydrogen sulfide removed), and compressed before being sent via pipeline to a centralized processing facility to which all Hilmar projects are connected (Picture 3).

After the removal of carbon dioxide, the biogas (now biomethane) is injected directly into the nearby PG&E utility line and marketed as an alternative renewable fuel for trucks and buses. By doing this, the projects qualify for Low Carbon Fuel Standard (LCFS) credits issued by the California Air Resources Board (CARB). These credits can be monetized to provide the dairies with a new revenue stream.

Since the commissioning of all the Hilmar cluster projects in December of 2024, the projects have produced approximately 250,000 MMBtu of ultra-negative carbon intensity RNG, which is equivalent to 1.8 million gallons of diesel. In addition, the Hilmar projects have also accounted for reductions of over 95,000 metric tons of CO2 equivalent to date, which is equivalent to removing nearly 4,245 diesel trucks from the road each year. After 10 years the five DDRDP-funded projects are estimated to reduce 595,093 metric tons of CO2 equivalent.

In addition to the local environmental benefits, the Hilmar cluster has also partnered with the Hilmar Unified School District to provide six scholarships of $3,500 ($21,000) continuing education scholarships each year for two years for Hilmar High School seniors, a total of $42,000. With 63.8% of Hilmar students being socioeconomically disadvantaged[1], the support from the Hilmar cluster has been a positive boost for the community’s youth in pursuing further opportunities and success.

The Hilmar cluster demonstrates how climate-smart agriculture can drive both environmental progress and community uplift. By converting dairy manure into renewable natural gas, the projects cut methane emissions and support California’s clean energy goals. Its benefits extend beyond the farm, helping to strengthen the local economy and invest in the long-term well-being of Hilmar’s residents.

“The Hilmar Cluster is helping reduce greenhouse gas emissions in the Hilmar area while producing renewable natural gas (RNG) for the trucking industry—supporting cleaner transportation and improved air quality across California. This project is one of many that demonstrates the dairy industry’s strong commitment to adopting sustainable practices and driving environmental progress,” said Charles Ahlem, Partner Hilmar Jersey’s LLC.

California Climate Investments and GHG Reductions

The Hilmar Cluster represents a major step forward in climate-smart agriculture. Five projects in the Hilmar cluster are supported by grant funding from California’s Dairy Digester Research and Development Program (DDRDP), administered by CDFA and funded through California Climate Investments (CCI).

“AMMP and DDRDP are part of California Climate Investments, a statewide initiative that invests billions from Cap-and-Trade dollars into reducing greenhouse gas emissions, boosting the economy, and enhancing public health and the environment—especially in disadvantaged communities.”

[1] California Department of Education, 2024, California School Dashboard – Hilmar High School Report, Hilmar High Summary | California School Dashboard (CA Dept of Education)