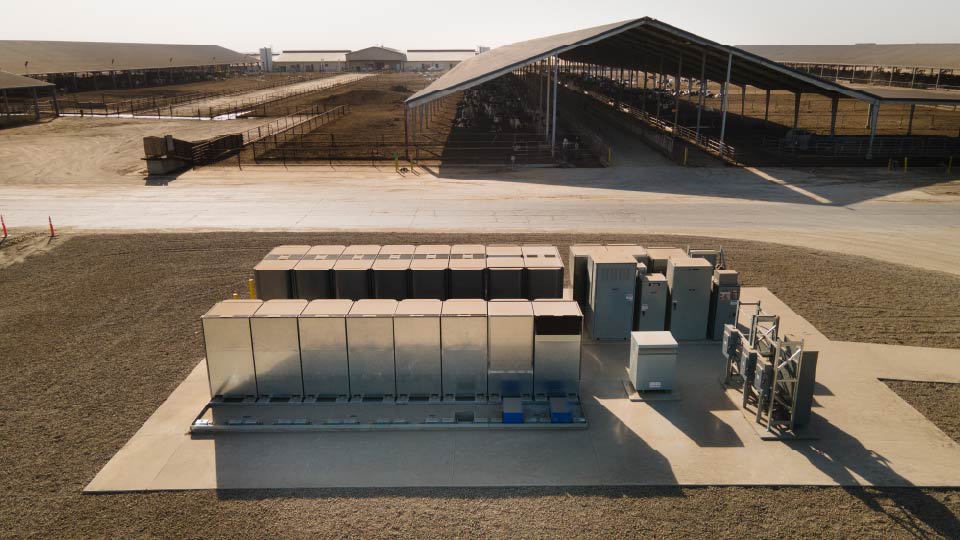

Vander Woude Dairy, a family-owned and operated business in Merced, California, has taken significant strides in sustainable agriculture by implementing a covered lagoon digester for methane capture. Established as a partnership in 2005, the dairy is now predominantly owned by Simon and Christine Vander Woude, who oversee 3,200 Holstein milking cows and 1,750 acres of farmland. In October 2020, Vander Woude Dairy began construction on a covered lagoon digester, part of the innovative Merced-South Cluster developed by Maas Energy Works. The digester became operational in November 2021, marking a new chapter in the dairy’s commitment to environmental stewardship.

The project, funded with over $1.8 million from the Dairy Digester Research and Development Program (DDRDP) through California Climate Investments (CCI) and an equal amount of matching funds from Vander Woude Dairy, cost $3.7 million. “The State of California’s proactive support of programs like the Dairy Digester Research and Development Program was instrumental in helping our project get off the ground. Our family run dairy has made consistent environmental improvements over the years, but we were hesitant to take the leap on a large investment in a digester system when the technology was still emerging. CDFA’s partnership with us and our neighbors helped us take the financial leap and their program has proven to be one of the most effective at enhancing the environmental sustainability of the California dairy industry in recent years,” said Simon Vander Woude.

CDFA forecasted that the digestor to reduce greenhouse gas emissions by around 18,800 metric tons of CO₂ equivalent (MTCO₂e) annually. However, the most recent 12-month data reveals that the dairy exceeded expectations, achieving nearly 24,000 MTCO₂e in reductions and injecting over 73,000 MMBTU of gas into the pipeline. The R-CNG produced by the Vander Woude Dairy Digester is injected into the utility pipeline to be used in large vehicles, qualifying it for credits under the state’s Low Carbon Fuel Standard (LCFS). These credits incentivize the production and use of low-carbon fuels, providing an additional revenue stream that supports the project’s economic viability while reducing greenhouse gas emissions in the transportation sector. These outcomes underscore the digester’s efficiency and its critical role in advancing California’s climate goals.

The Vander Woude Dairy Digester project is a model of sustainable economic development. Utilizing guidance from the Sacramento Regional Research Institute (SRRI), the project created 44 jobs—27 direct and 17 indirect—during its construction phase. These positions spanned various industries, including construction, operations, and related services, contributing an additional $825,858 in economic output for every $1 million spent.

Moreover, the project team partnered with Proteus Inc., a nonprofit dedicated to empowering disadvantaged communities in the San Joaquin Valley. Proteus facilitated local hiring, ensuring that 85% of piping contracts were fulfilled by residents near the project site. Training programs specific to renewable energy provided opportunities for individuals to develop skills aligned with California’s greenhouse gas reduction goals.

“For our family farm, ‘sustainability’ means doing more with less. Our dairy is the host of a hub-and-spoke model of methane digesters in Merced County, and all the dairies that send their gas to this hub are family farms. My wife, children, and I are laser-focused on efficient operations, producing milk with less impact to our climate,” said Simon Vander Woude.

By aligning with state and regional initiatives, the Vander Woude Dairy Digester embodies California’s vision for a sustainable agricultural future. Its innovative approach not only satisfies the need to reduce greenhouse gas emissions but also fosters economic growth and empowers the local community, setting a benchmark for dairy operations nationwide.